Green beans are a staple in many households, known for their crisp texture and fresh flavor. These beans, also known as string beans, are a great source of vitamins and minerals, making them a popular choice among health-conscious individuals. But have you ever wondered how these beans are processed before they make their way to your plate? In this article, we will take a closer look at how commercial green beans are processed.

Harvesting

Green beans are typically grown in warm climates, such as Florida, California, and Mexico. The harvest season for green beans usually lasts from May to October. The beans are harvested by hand or by machines that shake the beans off the plants.

Sorting and Grading

Once the green beans are harvested, they are taken to a processing facility where they undergo a series of sorting and grading processes. The first step is to remove any leaves, stems, or debris that may have come with the beans during harvesting. This is usually done by a machine that shakes the beans and uses air to blow away any unwanted material.

Next, the beans are sorted based on their size, shape, and color. This is an important step because it ensures that only the best quality beans make it to market. The beans are usually sorted by hand or by machines that use optical sensors to detect any defects in the beans. The sorted beans are then graded based on their quality and size.

Washing and Blanching

After the sorting and grading process, the beans are washed to remove any dirt or debris that may still be present. The beans are usually washed in large tanks filled with water and then drained.

The next step is blanching. Blanching is a process in which the beans are briefly boiled in hot water and then plunged into ice water to stop the cooking process. This helps to preserve the beans’ color, texture, and flavor. Blanching also helps to remove any bacteria or dirt that may be on the beans.

Packaging and Freezing

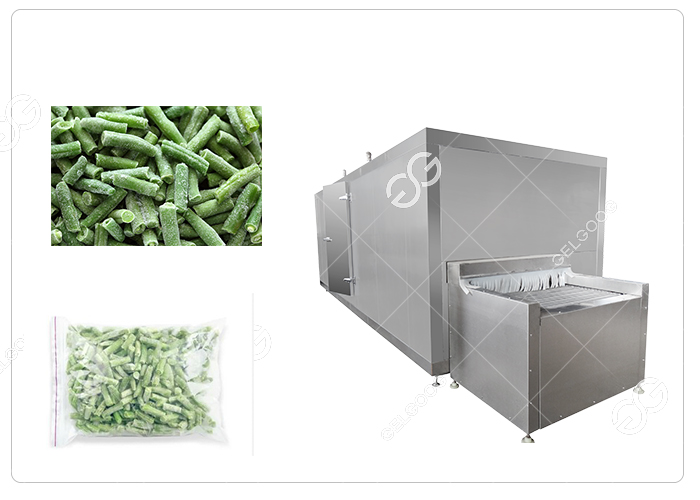

After blanching, the beans are drained and packaged for freezing. The packaging is usually done by machines that weigh the beans and seal them in plastic bags or containers. The packaging is important because it helps to protect the beans from freezer burn and keeps them fresh for a longer period of time.

The final step in the process is freezing. The beans are usually frozen at a temperature of -18°C (0°F) or lower. Freezing is an effective way to preserve the beans’ nutrients and flavor. Frozen green beans can be stored for up to 18 months.

Final Thoughts

Commercial green beans go through a rigorous process before they make their way to your plate. From harvesting to freezing, each step is carefully monitored to ensure that only the best quality beans make it to market. The next time you enjoy a serving of green beans, take a moment to appreciate the hard work that goes into processing them.

We are a manufacturer of frozen green beans processing line with many years of production experience, if you want to start a related business, we can provide solutions.