Description

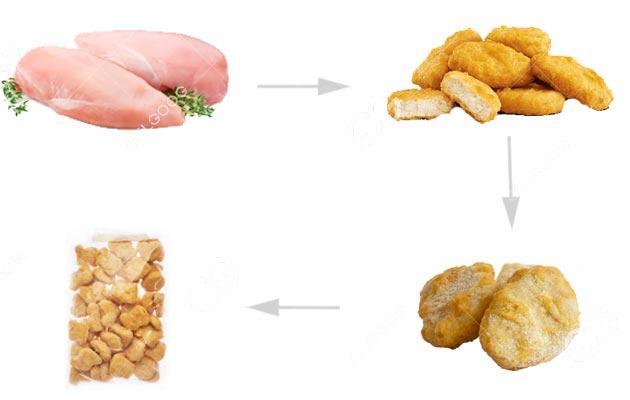

This frozen chicken nuggets production line has a compact design. The spiral quick-freezing machine saves ground space and can freeze a large number of monomers efficiently. The frozen output can reach 300-3000kg/h. Quick-frozen chicken nuggets can be used with the production line, or the quick-freezer can be customized separately.

Quick-Frozen Chicken Nuggets Production Line

- Chicken nugget cleaning machine: clean the dirt on the surface of the chicken nuggets to reduce bacterial contamination.

- Chicken nugget air drying machine: The surface of the chicken nuggets after cleaning will have excessive moisture. Use an air dryer to remove the excess moisture.

- Chicken nuggets wrapped in noodles or breadcrumbs

- Chicken nuggets frying machine: Deep fry the chicken nuggets evenly.

- Chicken nuggets iqf spiral freezer machine: The spiral quick-freezing machine is used to quick-freeze the chicken pieces. You can choose a single spiral or double spiral according to the output. This machine can freeze a large number of chicken pieces in a short time.

- Packaging machine: The frozen chicken nuggets are packaged and sold, and they are generally sold to food processing plants or supermarkets for secondary processing.

- Cold storage: The function of cold storage is to facilitate storage.

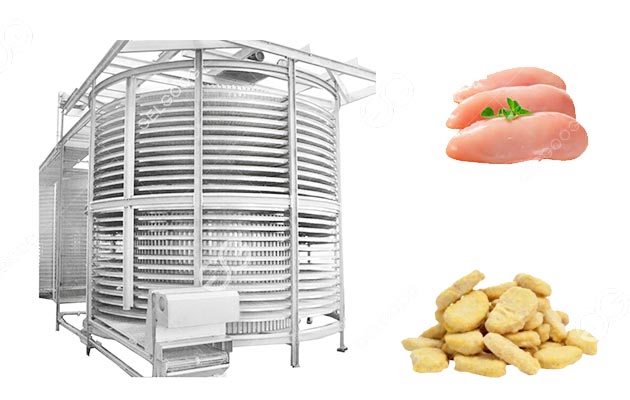

Chicken Nugget IQF Spiral Freezer Machine

This iqf spiral freezer machine is mainly composed of a transmission part, an evaporator, a library board, and an electrical device. The transmission part is composed of a transmission motor, a mesh belt, a turret, and an independent frequency converter. Our spiral quick-freezing machine is divided into single spiral and double spiral. The main difference is that the output of the double spiral is larger, and it is more suitable for thick and bulky products.

- Single spiral quick-freezer: suitable for meat, aquatic products, fruits and vegetables, ice cream, etc. It occupies a small area, has high efficiency, and the output is 300-1500kg/h. It is suitable for food with short freezing time and small output. Support customization.

- Double spiral quick-freezer: suitable for meat, prepared food, seafood, fruits and vegetables, pasta products, ice cream and other quick-frozen foods with long freezing time or large output. The output is 1000-3000kg/h. Support customization.

Advantages Of Chicken Nugget Spiral Freezer

- Compact structure, saving space, safe and reliable.

- Using high-quality stainless steel materials, in line with food safety standards

- Save energy and reduce production costs.

- The mesh belt adopts frequency conversion control, which can be adjusted according to different videos.

- This machine can be customized according to the actual needs of customers.

- Wide range of applications, suitable for a variety of products.

Scope Of Application

- Seafood: fish meat, shrimp, squid rings, clams, fans, etc.

- Meat products: chicken nuggets, beef, steak, lamb, lamb chops, pork, etc.

- Noodle products: dumplings, meatballs, buns, steamed buns, glutinous rice balls, bread, etc.

- Fruit and vegetable products: apples, mangoes, peas, broccoli, corn kernels, etc.

- Dairy products: yogurt, ice cream, etc.