Description

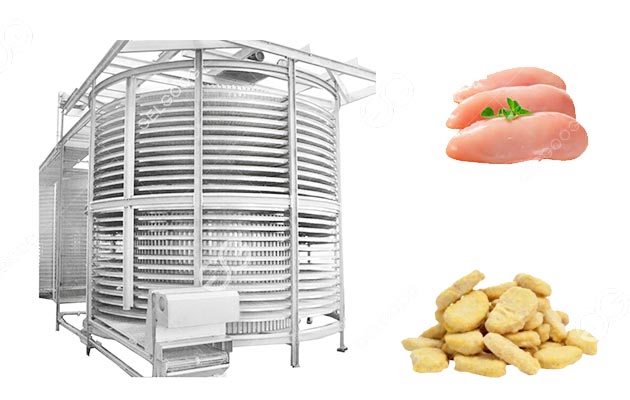

The fruit and vegetables vacuum freeze drying machine provided by our company is to freeze-dry the material in a low-temperature environment, which can keep the color, aroma, taste, shape, and nutritional content of the original food to the greatest extent, and the rehydration effect is excellent. Its application range is very wide: fruit and vegetable products, meat products, flour products, aquatic products, condiments, and so on. As a professional vacuum freeze dryer manufacturer, we can customize this machine according to customers’ needs

The vacuum freeze dryer machine operates by freezing the water content of an object in a vacuum and low-temperature environment, transforming it into a solid state, and subsequently sublimating the solid water into a gaseous state. As a result of this process, a dry, green, and environmentally friendly freeze-dried product is obtained. The fundamental principle underlying the operation of the vacuum freeze dryer machine is thus to solidify and subsequently vaporize the water content of the object being dried.

The components of the vacuum freeze dryer machine are mainly composed of six parts: drying chamber, condenser (water catcher), heating system, vacuum system, refrigeration system, and electrical control system.

Advantages Of Fruits And Vegetables Vacuum Freeze Drying Machine

- By drying under low temperature and vacuum conditions, the nutrients are well preserved, particularly the heat-sensitive components which are less likely to be damaged.

- The shape of the material remains unchanged because the sublimation and dehydration of ice crystals directly convert water from solid to gaseous state, leaving the skeleton of the food intact.

- Dehydrating at low temperature results in minimal changes to the physical and chemical properties of food, preserving the original color and preventing significant loss of pigments and fragrances.

- The fragrance of the food is largely preserved during the freezing process because the fragrant ingredients are concentrated in the amorphous part. Consequently, there is minimal loss of pigments and aromatic substances when the ice crystals vaporize.

- This dried food product rehydrates excellently, with over 95% rehydration achieved due to the many pores left by water after drying. Rehydration is also rapid, taking only a few seconds to tens of seconds.

- The high dehydration rate of this food product means it does not require preservatives and has a long shelf life at room temperature. Additionally, it is lightweight, does not need a cold chain for storage, and is convenient for storage and transportation, which helps to reduce costs.

Application Of Vacuum Freeze Drying Machine

The vacuum freeze dryer can well retain the nutrients, aroma, color and shape of the product, and has a good rehydration effect, so it is often used in the processing of various products.

- Fruit and vegetable chips: strawberry, banana, mango, fig, lemon, kiwi, yellow peach, jackfruit, dates, etc.

- Freeze-dried and dehydrated vegetables: carrots, cucumbers, okra, french fries, sweet potatoes, rapeseed, mushrooms, onions, garlic, green beans, corn, spinach, etc.

- Seafood: shrimp, fish fillet, crab meat, squid,

- Meat products: beef, pork, chicken.

- Prepared food, seasoning packs for instant noodles, instant products, etc.

We are a professional vacuum freeze dryer manufacturer if you want to get more details and quotation about this machine, please contact us.