Freeze-dried products has the characteristics of porous sponge-like structure, and moisture can easily enter when rehydrated. The main advantage is that the nutrients can be well preserved, and the preservation time can be very long. Since the food is dehydrated under vacuum conditions, the tissue inside the food is not easily damaged, and the smell and shape of the food will not change after rehydration. So what products are freeze dried with vacuum freeze processing?

At present, the more common freeze-dried products are as follows:

1. Freeze-dried staple food

It mainly includes instant noodles, instant rice, instant porridge and so on. The convenient staple food produced by vacuum freeze-drying technology has good taste, complete nutrient content and good rehydration. The drying effect is obviously superior to other drying methods, and because of low temperature operation, it is especially suitable for the production of nutritionally enhanced food.

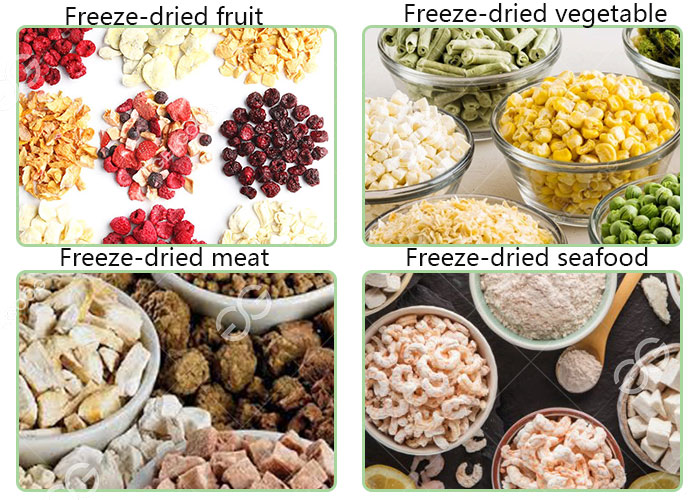

2. Freeze-dried meat products

Vacuum freeze drying can not only improve the quality of meat products, prolong the shelf life of products, and improve the grade of dried products, but also can make ready-to-eat meat products, enrich the types of meat products, and increase the added value and sales channels of meat products. Aquatic products are also a hot topic. The existing aquatic products on the market include shrimp, scallops, sea cucumbers, squid, soft-shelled turtles, sea stings, and sea vegetables.

3. Freeze-dried fruit and vegetable chips

Deep processing of fruits and vegetables to form dehydrated vegetables and freeze-dried fruits and vegetables, the excess water contained in fruits and vegetables is removed, and the chlorophyll and vitamins contained in fruits and vegetables can still be preserved. The original color, nutrition and flavor of fruits and vegetables. Freeze-dried fruit and vegetable chips are becoming more and more popular. The vegetables that are already available include tomatoes, peppers, lotus cabbage, cabbage, coriander, chives, onions, spinach, mushrooms, yams, broccoli, carrots, sweet potatoes, etc. Fruits also include strawberries , figs, longan, bananas, apples, cantaloupe, grass fu, pineapple, peaches, grapes, etc.

So how are freeze-dried products processed?

In fact, it is quite simple, and a vacuum freeze dryer manufacturers can do it. The main principle is to freeze the food at low temperature first, and then place it under vacuum for heating and drying, so that the moisture formed by freezing in the food changes from a solid state to a gaseous state and is volatilized, so it is also called sublimation dry food.

If you want to start a vacuum drying processing business, you can contact us. We are a vacuum freeze dryer manufacturer with many years of production experience and have exported equipment to more than 190 countries around the world. We can provide you with solutions to make your vacuum freeze-drying business a success.