In today’s fast-paced world, where convenience and health are of paramount importance, frozen vegetables have emerged as a lifesaver for many households. These vibrant and nutrient-packed options offer a convenient way to enjoy the goodness of vegetables year-round. If you’re an entrepreneur looking to tap into this thriving market, a frozen vegetable processing line could be your ticket to success. In this blog, we’ll delve into the world of frozen vegetable processing lines, exploring their benefits, key components, and why investing in one could be a game-changer for your business.

The Rise of Frozen Vegetables

Frozen vegetables have seen a steady rise in popularity over the years due to their numerous advantages. They retain a significant portion of their nutrients, colors, and flavors thanks to modern freezing techniques that lock in freshness. Plus, they eliminate the hassle of washing, peeling, and chopping, making meal preparation a breeze. With busy lifestyles becoming the norm, consumers are seeking nutritious options that save time without compromising on health, and frozen vegetables fit the bill perfectly.

The Process Unveiled

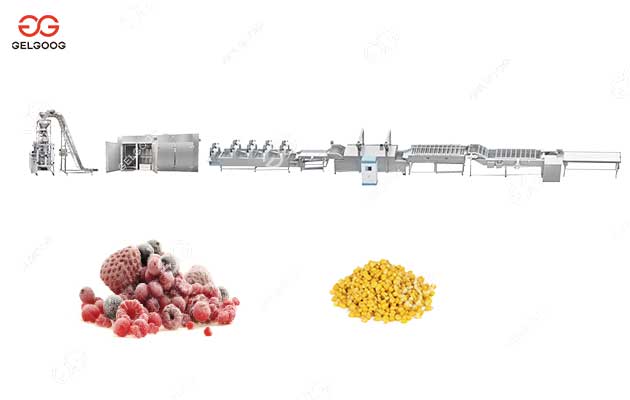

A frozen vegetable processing line for sale is a sophisticated system that transforms freshly harvested vegetables into premium frozen products. Let’s break down the key steps involved:

- Sorting and Washing: The journey begins with sorting to remove any damaged or inferior vegetables. They then undergo a thorough wash to eliminate dirt and contaminants.

- Blanching: The vegetables are quickly blanched in hot water or steam. This step helps preserve color, texture, and nutrients while also eliminating any lingering bacteria.

- Cooling: Rapid cooling halts the blanching process, preventing overcooking and maintaining the vegetables’ crispness.

- Cutting and Sizing: Depending on the product, the vegetables may be cut, sliced, or diced to the desired size.

- Freezing: The flash-freezing technique is employed to lock in the vegetables’ freshness. Rapid freezing prevents the formation of large ice crystals, which can compromise texture and flavor.

- Packaging: Once frozen, the vegetables are packaged in airtight, moisture-resistant bags or containers to prevent freezer burn and ensure a long shelf life.

- Storage and Distribution: The frozen vegetables are stored at ultra-low temperatures until they are ready for distribution to retailers or consumers.

Benefits of a Processing Line

Investing in a frozen vegetable processing line for sale offers several compelling advantages:

- Efficiency: A processing line automates labor-intensive tasks, reducing the need for manual intervention and streamlining production.

- Quality Control: Modern frozen vegetable processing line for sale come equipped with sensors and technology to monitor various parameters, ensuring consistent quality and minimizing waste.

- Preservation of Nutrients: The quick freezing process helps retain the nutritional value of vegetables, providing consumers with a healthy and convenient option.

- Diverse Product Range: These lines can handle a variety of vegetables, allowing you to offer an array of frozen products to cater to different tastes and preferences.

- Market Demand: The growing demand for convenient yet nutritious food options presents a lucrative market opportunity.

Conclusion

As the frozen vegetable market continues to thrive, investing in a state-of-the-art processing line can position your business for success. By efficiently transforming freshly harvested vegetables into premium frozen products, you’ll cater to the demands of modern consumers seeking convenient, healthy, and delicious options. With the right processing line, you can embark on a journey that not only benefits your business but also contributes to the well-being of countless households. So, take the leap into the world of frozen vegetable processing and unlock a world of possibilities!